Our horns are effective in numerous applications.

Acoustic cleaners provide an effective solution to buildup and material flow problems within a wide range of industries.

Selective Catalytic Reduction

Acoustic Cleaning Systems, Inc. has become the vendor of choice for acoustic cleaners within the utilities industry. Acoustic energy is a viable and effective technique to clean SCR catalyst and has been spec’d in on new SCR’s since the late 1990’s. The acoustic energy emitted by the acoustic cleaners is non-erosive to the catalyst modules. ACS has supplied 1000’s of acoustic cleaners for SCR applications and with the introduction of the Magnum has simply blown their competition away!

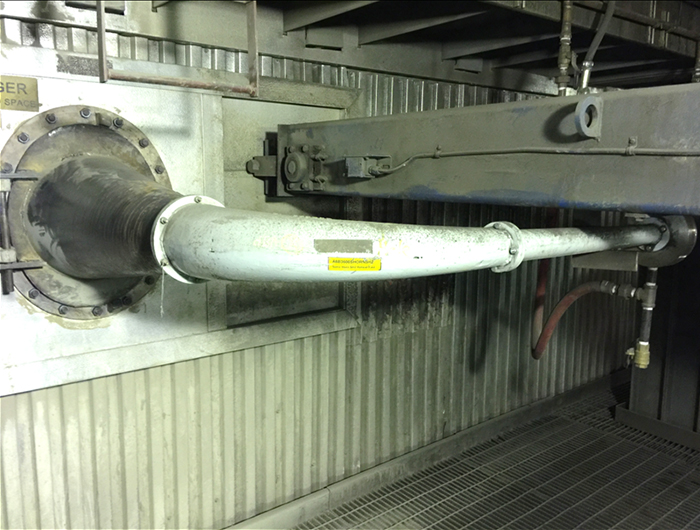

Electrostatic Precipitators

Sonic horns are proven alternatives to supplement and in some cases completely replace mechanical rapping systems on collection surfaces, electrode wires, and inlet distribution plates. Elimination of hopper pluggage can be achieved by installing units in the hoppers typically on a pokehole. Acoustic cleaning improves efficiency, increases precipitator uptime, reduces precipitator maintenance, and may prevent grounding problems. Sonic horns also effectively clean turning vanes.

Heat Transfer Surfaces & Boilers

Acoustic cleaning is a proven alternative to conventional steam sootblowers in boilers burning fossil fuels and waste fuels. Acoustic cleaners can be used to supplement and even replace steam sootblowers in certain applications. Units have been applied in superheaters, generating sections, economizers, horizontal re-heat, and airheaters. Advantages of acoustic cleaning include reduction or elimination of opacity spikes due to more frequent cleaning, reduction of steam sootblower cycles for steam savings, and lower maintenance costs.

Fabric Filters & Elements

Acoustic Cleaners are a proven method for cleaning in reverse air and shaker type baghouses. The units are effective in reducing pressure drop, increasing bag life, decreasing manual cleaning, and reducing hopper pluggage. There are also potential applications in Pulse Jet Collectors – Cleaning of the elements if the compartments can be isolated – and in the hoppers.

Other Applications

ID Fans

ACS acoustic cleaners can be applied to eliminate out of balance conditions, clean inaccessible parts, create a uniform cleaning pattern, and reduce the frequency of manual cleaning. Acoustic cleaning may also reduce fan horsepower requirements.

Dryers

Acoustic energy is a successful way to eliminate unwanted buildup on walls of spray dryers and reduce product cave-in's. Acoustic Cleaners also aid in the discharge of products from RVDs (rotary vacuum dryers), tumbling, fluidbed, tray, and pan dryers between batch changeouts.

Hoppers

ACS acoustic cleaners have been applied to eliminate ratholing problems, bridging problems occurring in hoppers, and buildup on vertical walls. Sonic horns are successful in fluidizing a variety of products ranging from flour to fly ash. Other advantages include increased product flow and elimination of structural damage caused by vibrators.

Custom Applications

We're continually searching for new applications for our acoustic cleaner product line. Let our technical team analyze the factors specific to your application. With our extensive field experience in the application and installation of acoustic cleaners, we will custom design an acoustic cleaning system that is most effective for you.

Our horns aren't limited to the applications above. Companies from all sorts of industries are finding our products save them time and money while reducing the need for regular maintenance.

Cosmetic

Waste to Energy Plants

Food Processing

Detergent

Flour

Power Generation

Material Handling

Smelting

Chemical

Wood Processing

Pharmaceutical

Refinery

Cement

Gypsum

Steel Industry